The zero-point positioning system, as a flexible fixture, was first developed and manufactured abroad. With the recent transformation and upgrading of the manufacturing industry, it has gradually been applied in fields such as automotive and aerospace in China. Compared to traditional clamping and positioning solutions, the zero-point positioning system offers significant advantages in positioning accuracy and changeover efficiency, while continuously enhancing production line automation, simplifying process planning, reducing tooling design costs, and increasing production line flexibility.

Currently, industrial production models are gradually shifting from mass production of single parts to flexible and variable-batch production. Particularly in industries such as aerospace, where small batches and complex single-part processing are common, machining time accounts for only about 30% of the total processing time in traditional solutions. Meanwhile, with the proposal of "Made in China 2025," the introduction of new production models such as smart manufacturing, digital manufacturing, and networked manufacturing has led to rapid market changes, placing new demands on the iteration speed of parts. This has created an urgent need to enhance the flexibility of machining methods. The zero-point positioning system, also known as a pallet quick-change system or master-sub fixture, is a type of flexible fixture.

By using flexible fixtures, the flexibility of machine tool changeovers and line transitions can be significantly improved, while equipment downtime is reduced, utilization rates are increased, and production efficiency is multiplied. As a flexible fixture, the zero-point positioning system can be applied in various scenarios, whether in milling, turning, or special machining processes, or in three-axis, four-axis, five-axis, vertical, or horizontal equipment, and even in inspection equipment.

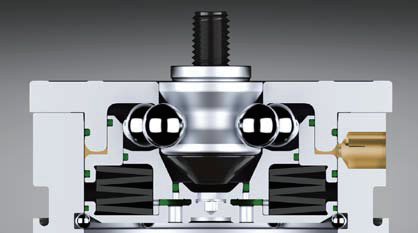

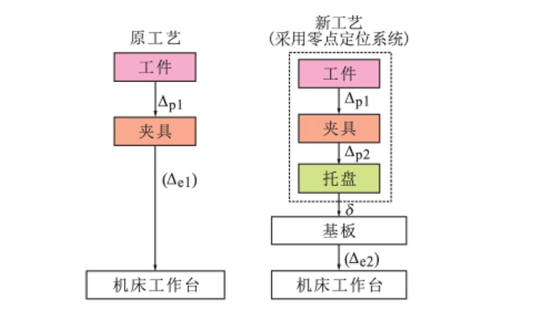

The essence of the zero-point positioning system lies in adding an intermediary connection between the fixture and the machine tool. During changeovers, the disassembly and assembly of the chuck and pull stud replace the disassembly and assembly of the original fixture. Since the repeatability of the zero-point positioning system is higher than that of the original fixture and far exceeds process requirements, the workpiece can always remain in the same position within the machine tool coordinate system, regardless of how many times it is disassembled and reassembled. This eliminates the need for re-zeroing and prevents secondary clamping errors, effectively maintaining the workpiece coordinate system's zero point, which is the origin of the name "zero-point positioning."

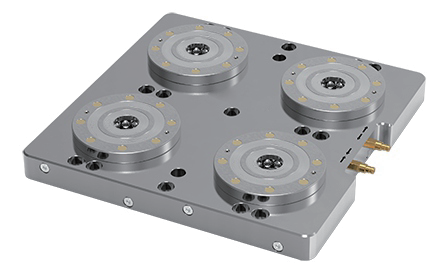

The core of the zero-point positioning system is the chuck, which is disc-shaped and serves as the main component for positioning and clamping. The central hole is used to insert the pull stud for locking, while the circumferentially evenly distributed holes are used to mount the chuck onto the base plate. Some standalone chucks, equipped with their own pipeline connectors, can be directly installed on the machine tool table without a base plate, offering greater flexibility.

The pull stud is the dedicated connector of the zero-point positioning system, responsible for the quick locking and release of the chuck's internal locking mechanism. The unique shape of the pull stud's outer profile allows it to engage with the locking mechanism, ensuring reliable locking without loosening. The upper end of the pull stud is fastened to the pallet or workpiece via threads, while the lower end features a circular platform and short taper for high-precision positioning. Depending on the functionality of the positioning solution, pull studs come in three types: precise positioning, single-direction floating, and fully floating. Compensating pull studs include special structures that allow for a certain degree of error in one or two directions.

Base plates and base mounts belong to the same category of components, serving as the foundation for mounting multiple chucks. They integrate internal pneumatic and hydraulic pipelines, directly connecting with the chuck's pipelines without the need for external piping, and consolidate multiple pipelines into a single interface for connection to external lines.

In new processes based on the zero-point positioning system, the error increases from Δp1 to the combined influence of Δp1, Δp2, and δ, making process design more stringent. However, since fixture interference may require multiple workpiece clampings, or efficiency considerations may necessitate the sequential use of roughing and finishing machines, or different types of machines and inspection equipment may be required due to process needs, multiple clampings are often necessary to complete machining. This makes the new process more friendly to process design.